Software developer notes

How to break automotive engine for 1$?

2024-05-31

Meet my old buddy - Hyundai Accent LC 2007.

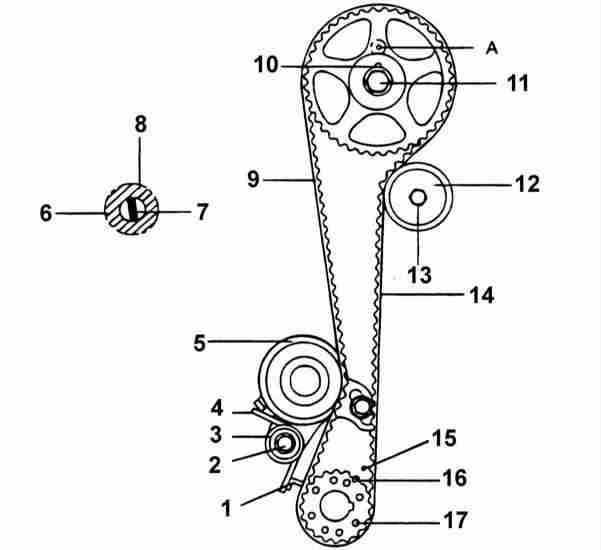

It was assembled by TagAZ, but as many other korean vehicles it has gasoline 16-valve G4EC. Its valve train contains two camshafts mechanically connected by a chain.

The exhaust camshaft is synchronized with the crankshaft via a rubber timing belt circled by two bearings.

At glance it's pretty simple engine without phase shifters, variable intake system, GDI etc. But its timing belt requires periodic (about 80000km) maintenance, otherwise cylinder head can be damaged by belt's breakage. Also this engine has feature, which allows you to perform test launching without alternator, power steering and AC belts. All you need is correctly installed timing belt and crankshaft's pulley (PAY ATTENTION!).

Last time I had changed the belt, pulley was not installed because I thought that shaft key fixes crankshaft's gear. Big mistake! It turns out that G4EC's shaft key has a shape like closed arc (instead of rectangular in other models).

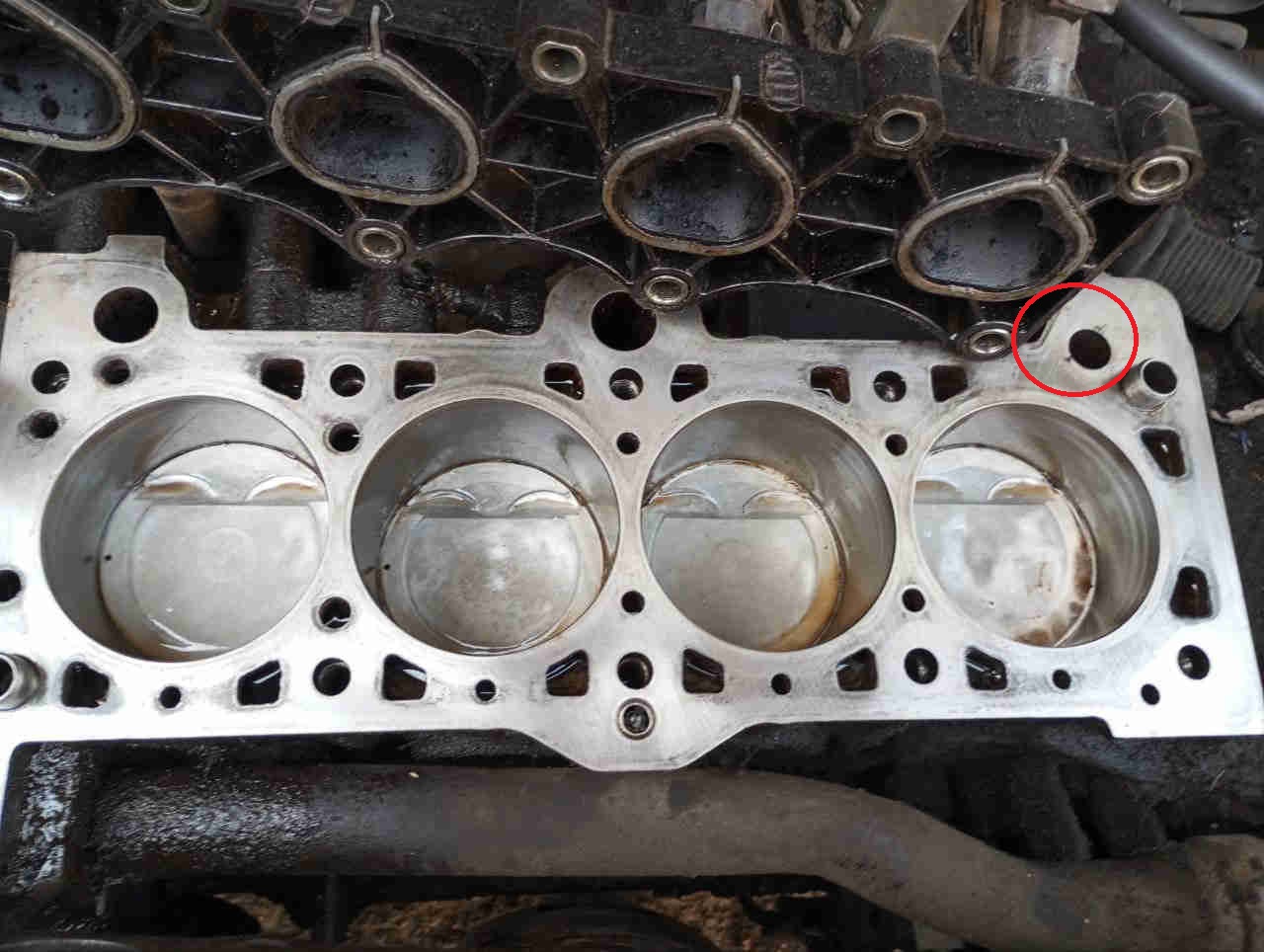

Under centrifugal forces the key will be detached without the fixed pulley. This happened exactly in my case! Next compression test detected leakage (about 0 bar) at the second cylinder. It's clear sign to disassembly and repair the engine. So below I breifly described some repairment's moments.

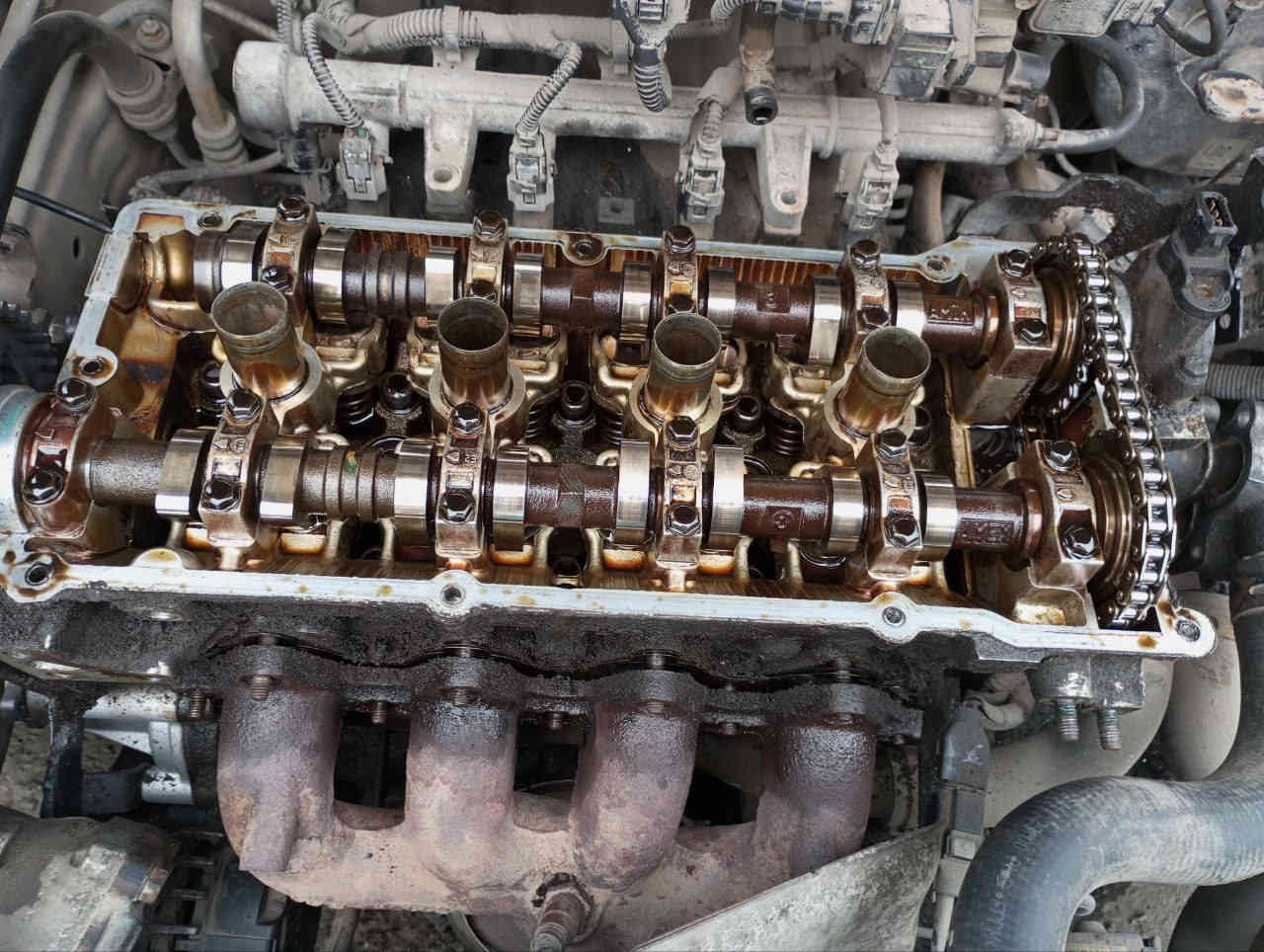

This is what inside (yes, engine had some oil consumption and I cleared it, you can see oil in other places).

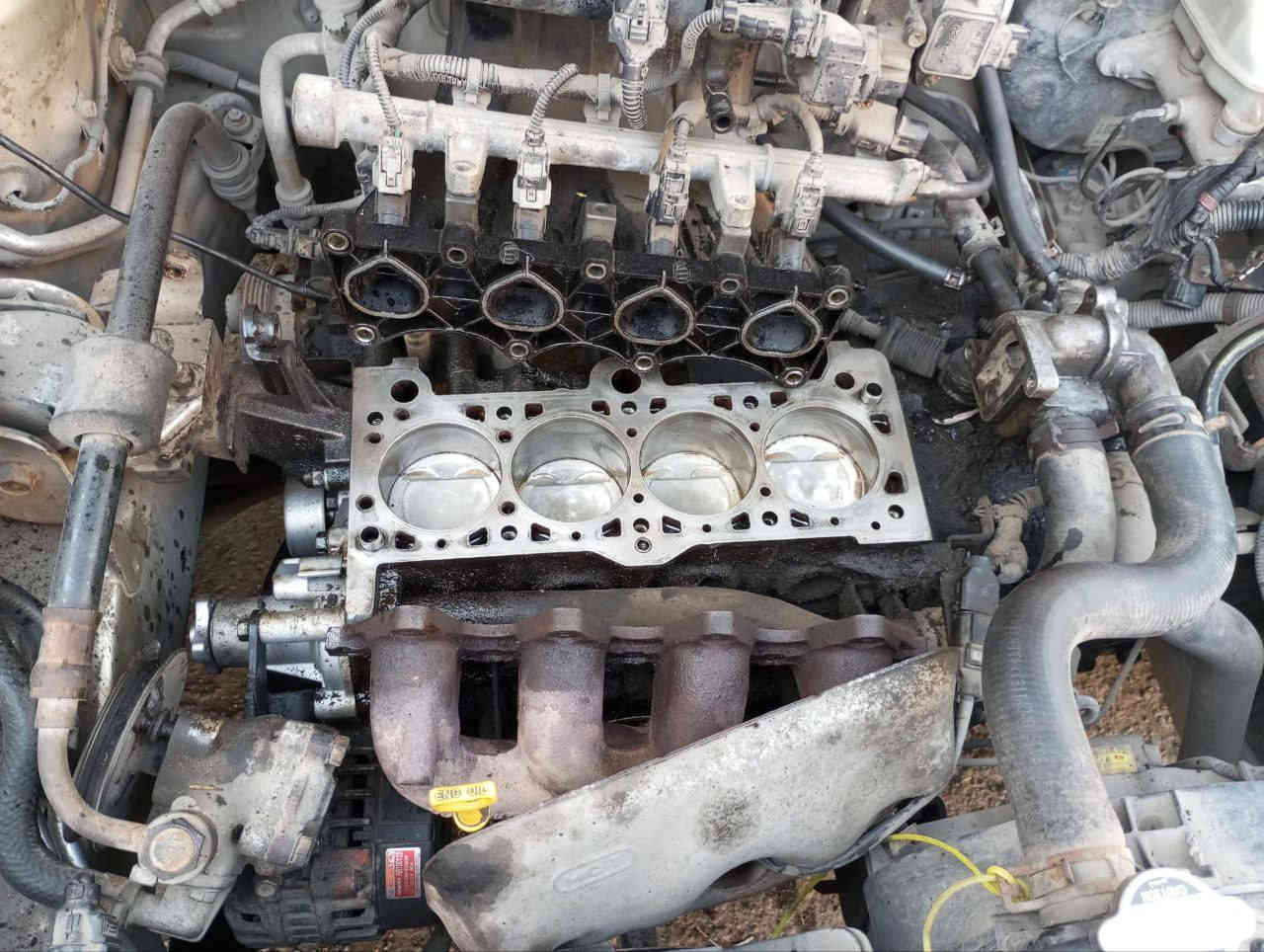

Bent intake valves say hello.

During cilynder head's disassembly you should be very careful - I used a small bit and it was accidentally dropped into oil drain hole (see red selection at image below). It had to disassembly a crankcase oil pan too.

Hydraulic valve lifters had oil coking, some of them had weak springs. (Note professional tool to disassembly the lifters)

I am not car mechanic and I don't have a workshop, so overall time took about 2 months (at last days someone tried to hack my car so I speeded up). All my mistakes were fixed and at the moment the car have passed about 700km. If you like similar stories, I highly recomend to read this article (unfortunately translation is needed) which inspired me. It's about the guy who assembled engine inside flat!

About me

Hi! I am Alex, the author of this blog. Here are my technical (in the majority) thoughts and stories. I will be hoping that you find this site interesting and fun. Also you can feel free to contact me (support for comments will be added later).