Software developer notes

Rear Window Defroster Repair. Part 1

2018-09-22

So, the soldering kit finally arrived and I decided to get started on fixing the rear window defroster.

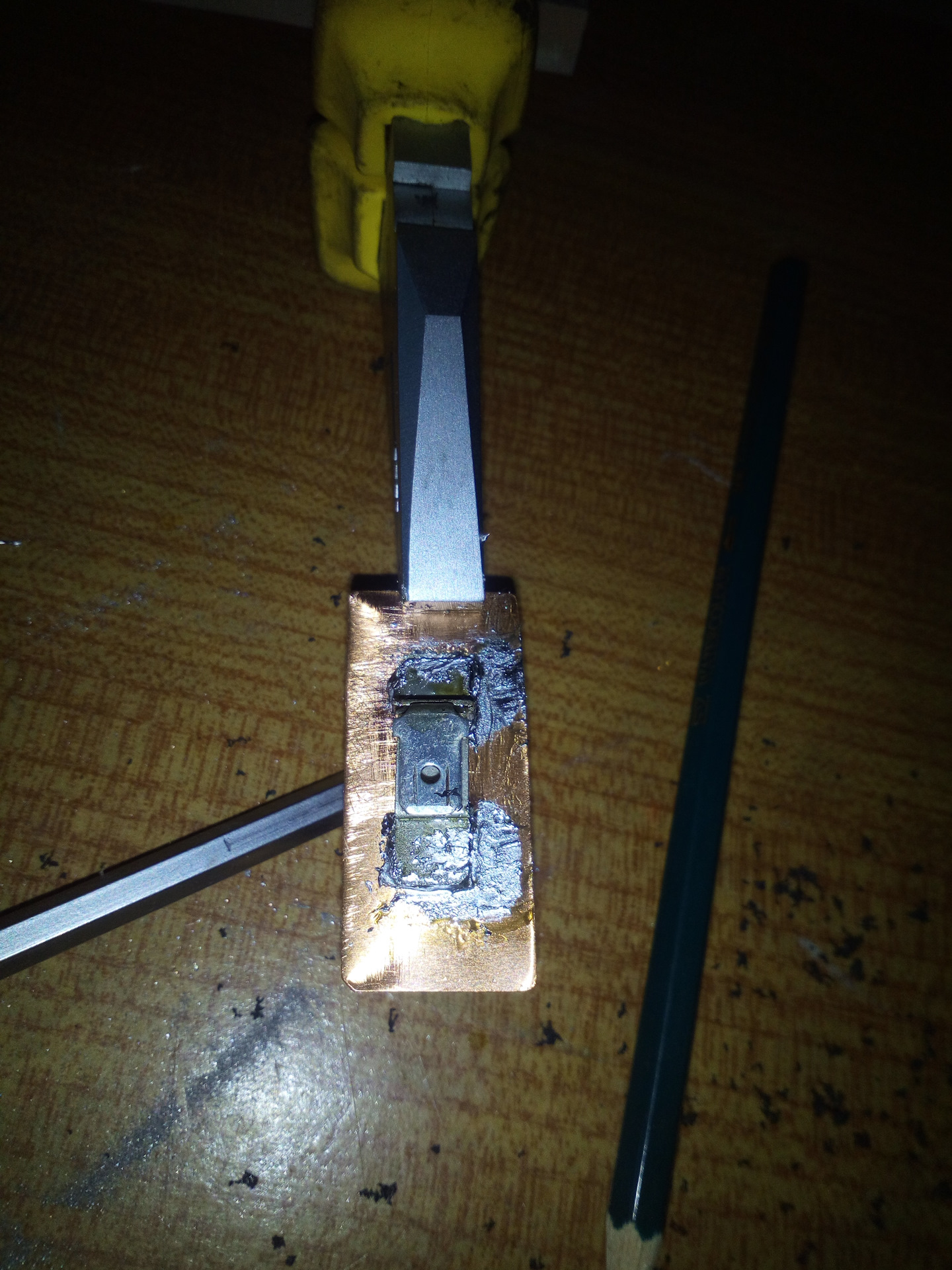

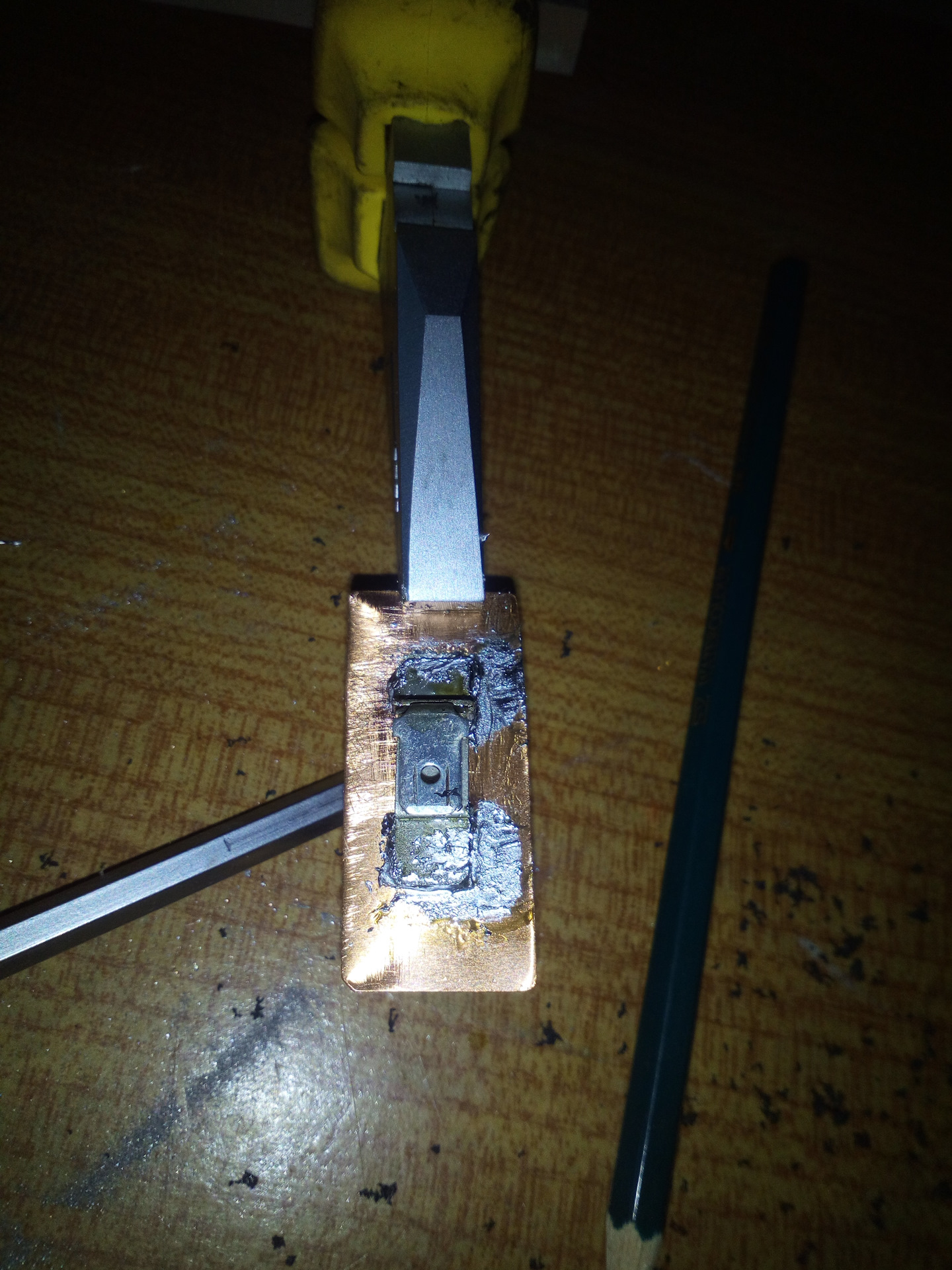

So, the soldering kit finally arrived and I decided to get started on fixing the rear window defroster.I decided to fix it like this: solder the detached contact to a copper plate, which I would then glue to the glass. Some people use low-melting-point solder and heat the glass — but I was afraid of heating the glass and soldering, especially since my soldering iron doesn't have temperature control. So, I bought a copper plate at the radio market (the nearest scrap metal shop didn't have the right plate, unfortunately, so I decided to buy one at the market — more expensive but faster), and cleaned the old solder off the terminal. I cleaned the contacts. This was my first time soldering, so my first attempt was a failure. I'll say right away, in my inexperience, I bought POS 40 solder, and that was a BIG mistake; it takes longer to melt, and instead of forming a proper mixture, it balls up. I guess everyone who does this probably knows that, but I fell for it. After soldering the terminal, I cleaned the area on the glass where I would be gluing with an eraser and decided to use conductive glue. The salesman really talked up this glue. The lack of any specifications on the packaging bothered me, but I decided to try it. Well, it's NOT EVEN glue! Just some watery stuff mixed with God knows what. It doesn't even make your fingers stick together. So, I HIGHLY ADVISE everyone against buying conductive glue in this kind of packaging. I'll have to look for another glue, or maybe try to make my own (mix graphite with regular Moment glue — but I'm not sure what the resistance would be like). Sorry, there won't be many photos.

P.S. I bought myself some halogen lamps.

About me

Hi! I am Alex, the author of this blog. Here are my technical (in the majority) thoughts and stories. I will be hoping that you find this site interesting and fun. Also you can feel free to contact me (support for comments will be added later).